PT. ANT21 INDONESIA

PERUSAHAAN PENGOLAHAN AIR LIMBAH INDUSTRI

Water / Wastewater Treatment

Rukan Gading Bukit Indah Blok H No. 18

Kelapa Gading, Jakarta Utara 14240 Indonesia.

• Tel : 021 2245 9153

• Mobile : 0822 4625 5758 / 0813 9824 3323

Our Product

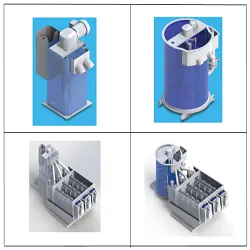

① High Efficiency Diffuser

① High Efficiency Diffuser♧ Feature

• Highest possible fine bubble SOTE.

• Durable, impact-resistant.

• Non-clog, trouble-free efficient operation.

• Designed for resistance of compressed air heat in continuous operation.

• Easily adaptable to various types of existing basin.

• Reduce energy consumption with maximum transport efficiency

at low air flow rate High oxygen transfer rate

can be maintained continuously

• Operates during all seasons, even during severe conditions of plant

with high oxygen transfer rate.

• Low power consumption, durable.

• Triangulary arranged cone shape minimizes bubble coalescene

Bubbling occurs evenly over each cross-section

with a wide range of airflow.

♧ Application

• Wastewater treatment plant

• Sewage treatment plant

• Aeration tank,

• Livestock wastewater treatment plant

• Filtration plants

♧ Properties

• Size : D = 327mm

• Dispersive Formation : Cross-section / Entire circular body

• Material : ABS Copolymer , Nylon Connector : 20A (Socket)

• Air flow rates : 60~130L/min

♧ Customer

• PT. HYUNDAI INTI DEVELOPMENT / CIKARANG

• PT. SAMA INDAH / BANDUNG

• PT. MEWAH NIAGA JAYA / BANDUNG

• PT. SINAR PANGJAYA MULIA / BANDUNG

• PT. JERDYTEX / BANDUNG

• PT. ORIENTAL EMBROIDERY / BANDUNG

• PT. KEMARGA KURNIA TEXTILE INDUSTRY / BANDUNG

• PT. HARAPAN TEXTILE INDONESIA / BANDUNG

• PT. TAK INDONESIA

⑤ Horizontal,

⑤ Horizontal, External Gear Pump

with Built-in

Relief Valve

[200㎡/h ×~7kg/㎠]

♧ Usages and applications

01. Application

Lubrication oil, Fuel oil or other liquids with lubrication property.

02. Differential pressure

Up to 7kg/cm²

03. Bearing

Internally setted metal bearing, lubricated by the pumping liquid.

04. Shaft sealing

Gland packing or mechanical seal.

05. Relief valve

Built-in type, Setting pressure

: minimum 2.2kg/cm² maximum 7.2kg/cm²

06. Pumping temperature

Up to 70°C

07. Flanges

KS or JIS 10kg/cm², rating. FF.

08. Standard capacity

Calculated at 25.8cst. (Rw.No.1, 100sec.)

Rpm-slip of motor considered

* The out of the above range can be supplied

according to customer’s order placement

♧ Operating data

Capacity : 40m³/Hr ~ 200m³/Hr

Head : 3Kg/㎠ ~ 7Kg/㎠

Suction Bore : Ø150mm ~ Ø250mm

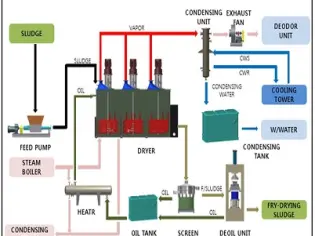

② Sludge Dryer

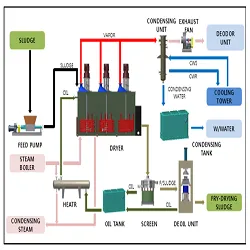

② Sludge Dryer (Sludge Fry-Drying System)

♧ Fry-Drying System ?

■ Process description

1. Sludge Storage Tank & feeding system.

- Sludge in the store tank is transferred to the reactor

with a pump or screw conveyor.

2. Reactor ( dryer).

- The sludge charged into the reactor is dispersed in the hot

oil by a high speed agitator (Temp: 130-150C).

-The moisture in the sludge is evaporated by the hot oil and

the moisture is turns into steam.

-The sludge whose moisture has been removed is discharge

to the outside by the conveyor.

3. Screen system.

- Fried sludge in the oil is seperated by oil and sludge in

the vibrator screen.

4. Pressing Unit.

-After screening, remove any remaining oil from sludge by pressing.

5. Condensing unit.

-when the moisture in the sludge becomes vapor and exits

to the outside, it is condensed by the heat exchanger.

6. Deodor Unit

- A trace amount of gas that can nit be condensed is

removed from the odor preventation facility.

7. Condensing Tank.

- The condensate removed from the heat excharger is sent

to the existing waste water treatment plant.

8. Oil Circulation Tank.

- After passing the screen, the oil is brought back into the reactor.