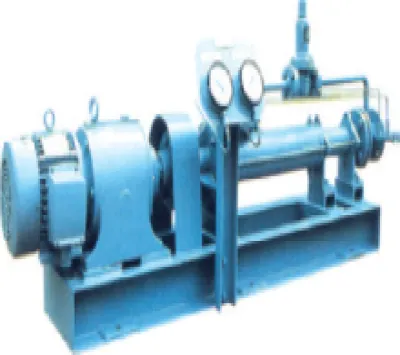

⑬-2 Horizontal,

Eccentric Mono

Screw Pump

01. Sewage treatment, Chemical, Ceramic, Construction,

and Hining industry

02. Food, Beverage, Sugar and Starch industry,

Pharmaceutical industry.

♧ Principle

Eccentric Screw pump consists of a single helix metal rotor

which rotates eccentrically within an elastomeric stator

with a double helix form. The interference fit between the rotor

and stator creates a constant cavity which carries the pumped product

continuously through the pump.

♧ Design and operation features

01. Eccentric Screw Pump conveys easily high viscous

and high dense material.

02. Uniform, Non-pulsating flow.

03. High suction capability.

04. Vulcanized-in, Easily replaceable stator,

Torsion-proof, therefore a Long service life.

♧ Operating data

Capacity : 1m³/Hr ~ 75m³/Hr

Head : 1Kg/㎠ ~ 5Kg/㎠

Suction Bore : Ø40mm ~ Ø125mm

MORE PRODUCT

Single Stage,

Volute Casing,

Centrifugal

Screw Pump,

Foot Mounted Type

■ Non-clog pump for unscreened sewage and sludges.

♧ Usages and applications

For the applications and services such as unscreened

sewages, sludges, waste water, raw water, food-stuffs waste,

paper pulp, slurry, gas-entrained liquid, fibrous liquid,

fish, etc, transfer and feed in the waste treatment plant

and various branches of industry.

♧ Design and operation features

01.By combining design theories of volumetric screw pumps

and centrifugal pumps, improved the design of

conventional non-clog pumps.

02. Steep curve of performance enables easy control of capacity.

03. Power consumption is not so much sensitive to the

variation of flow.

04. Suitable for pumping of liquids with high viscosity

or containing solids.

05. Clearance between the impeller

and the suction cover is adjustable.

06. Impeller back pull-out design.

07. Counter Clock wise(CW) rotation

when viewed form the driver end.

08. Uncooled stuffing box. Packing rings or mechanical seal.

09. Roller bearing and ball bearing. Oil bath type lubrication.

10. Welded steel base plate, machined both up side and bottom side.

11. Flange : KS D 4308

* The out of the above range can be supplied

according to customer’s order placement.

♧ Operating data

Capacity : 0.05m³/min ~ 35m³/min

Head : 3m ~ 92m

Suction Bore : Ø80mm ~ Ø600mm

Eccentric Mono

Screw Pump

♧ Use and applications

01. Sewage treatment, Chemical, Ceramic, Construction,

and Hining industry

02. Food, Beverage, Sugar and Starch industry,

Pharmaceutical industry.

♧ Principle

Eccentric Screw pump consists of a single helix metal rotor

which rotates eccentrically within an elastomeric stator

with a double helix form. The interference fit between the rotor

and stator creates a constant cavity which carries the pumped product

continuously through the pump.

♧ Design and operation features

01. Eccentric Screw Pump conveys easily high viscous

and high dense material.

02. Uniform, Non-pulsating flow.

03. High suction capability.

04. Vulcanized-in, Easily replaceable stator,

Torsion-proof, therefore a Long service life.

♧ Operating data

Capacity : 1m³/Hr ~ 75m³/Hr

Head : 1Kg/㎠ ~ 5Kg/㎠

Suction Bore : Ø40mm ~ Ø125mm