Fiber Filter

CF Filter (Pore Control Fiber)

Non-woven fine fibers wrapped around the perforated pipe are squeezed,

After filtration, relax it and increase the pore size,

(PCF) filter with a pressure-type fiber filter.

And the reverse filter function is applied to the cartridge filter.

Flexible fiber bundles surrounding the perforated cylindrical

strainer are pulled up to form fine pores at filtration step and

they are released to form rough pore for easy and intensive

backwash. Its name is PCF(Pore Control Fiber) Filter that

is the cartridge filter having backwashing function.

Gravity Flow Fiber Filter (GFF Filter)

Non-woven fibers fiber woven fabric wrapped with hollow plates,

pressing air gaps, After filtration, relax and increase pore size,

Is a gravity filter fiber, called GFF (Gravity Flow Fiber) Filter,

Because upstream water filtration is automatically supplied to

reverse wastewater by upward flow formation, filtering and backwash

Pumps are not required and operating costs are reduced.

Filter with 30cm differences of water level after pressurizing unwoven

fine fiber onto the perforated rectangular strainer to form fine pores,

and then backwash after releasing fiber bundles to make the pore wide

for easy and intensive backwash. Its name is GFF (Gravity Flow Fiber)

Filter. When multiple GFF basins are installed, the backwash water are

automatically supplied from adjacent basin's filtrate without back wash pump.

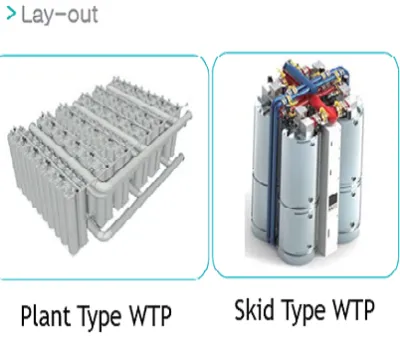

1/100 WTP

1/100 WTP dramatically reduces entire process

time within only 3 mins. as well as 1/100 of treatment volume,

1/5 of construction period and 1/3 of Capex & Opex

while Hyatt (1884, USA) had invented RSF (Rapid Sand Filter

- Coagulation/Sedimentation/Sand filtering) process

to produce tap water 5 hours that is used to almost 100%

of WTP in the world.

1/100 WTP treats about 20 NTU of raw water to

below 0.3 NTU for river water through its own fiber filtration

system in real time. This facility is suitable & designed

for small & medium capacity such as below 20,000 m /day

is container or skid type and bigger capacity is plant type

and especially for the purpose of disaster relief such as earthquake,

etc. is applied to mobile type.

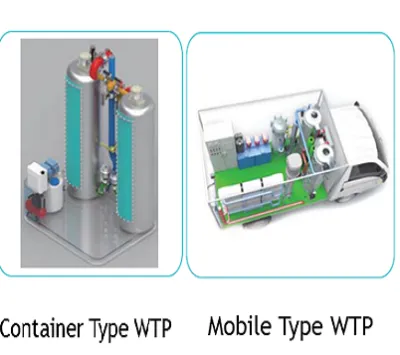

OASIS / WTP-C/db

• Container WTP diffusion brand

Diffusion brand Container type water treatment process

is a process that produces drinking water by using PCF(HS) filter which

is composed of 1 or 8sets of PCF filters, In case of 1set of pcf filter unit,

back wash water is supplied by installed back wash topside tank and

2sets of PCF filter unit, back wash water is supplied by next working

PCF filter. 3 point chemical dosing system will apply to raw water de

pending on turbidity change runs automatic operation,

OPEX is low, easy to control and moving installation.

OASIS / C-WTP

• Container WTP

Container type water treatment process is a process

that produces water by SMiDF(Single Mixing & Double Filteration)

process, which rapidly compounds river or lake water with coagulant

and directly filters the mixture using 2-step PCF.Having 1/100 retention

time by instant coagulation, direct fiber filtration processes taking 3

mins against the conventional coagulation, sedimentation and sand filter

processes taking 300mins, turbidity of treated water is below 0.3

NTU and SDI 3.0, when turbidity of source water in within 20NTU.

Construction period is short and OPEX & CAPEX is low. Container type

using ISO 10, 20, 40, 45ft is designed as the format of 1 or 2 layer.

OASIS / WTP-C/uw

• Container WTP - C/uw

Container type water treatment process for Fe• Mn removal is a

process that when solubility of Fe•Mn exceed

3 times of standard limit for underground water, it will rapidly

oxidation and mix with coagulant using PCF(HS) filter filtrate

plant. It compounds with one oxidizing chamber & one filter

tank and which has for both filtration water tank and back wash

tank located on the upper part and both automatic operation

and manual operation is possible depending on water level

so OPEX is low, easy to control and moving installation.

7. OASIS / M-WTP

• Mobile WTP

mobile type WTP consists of 2 to 6 units of filter which

applies an independent back wash system and back wash water

is supplied from the other filter and activated carbon filtration

device. This full automatic operation is applied with 3 point chemical

dosing system, automated fault diagnosis system and

back wash recycle system.

8. OASIS / P-WTP

• Plant WTP

plant type WTP that is direct filtration process by PCF

fiber filtration with instant mixing of coagulant for raw water

as river or lake water is for medium & big size WTP. It is full

automatic operation system and applied 3 point ch dosing

system, automated fault diagnosis system and back wash water

recycle systemas well as minimized factory space,

construction peirod, Capex and Opex.

9. OASIS / S-WTP

• Skid WTP

skid type WTP consists of 4 to 8 units of filter which

is an independent back washsystem and back wash water is

supplied from the other filter. This is full automatic operation

system and applied 3 point dosing system, automated fault

diagnosis system and back wash water recycle system. Skid

type is available to apply at small place than container type's

by heighten of PCF height and easy to move.

Non-woven fine fibers wrapped around the perforated pipe are squeezed,

After filtration, relax it and increase the pore size,

(PCF) filter with a pressure-type fiber filter.

And the reverse filter function is applied to the cartridge filter.

Flexible fiber bundles surrounding the perforated cylindrical

strainer are pulled up to form fine pores at filtration step and

they are released to form rough pore for easy and intensive

backwash. Its name is PCF(Pore Control Fiber) Filter that

is the cartridge filter having backwashing function.

Gravity Flow Fiber Filter (GFF Filter)

Non-woven fibers fiber woven fabric wrapped with hollow plates,

pressing air gaps, After filtration, relax and increase pore size,

Is a gravity filter fiber, called GFF (Gravity Flow Fiber) Filter,

Because upstream water filtration is automatically supplied to

reverse wastewater by upward flow formation, filtering and backwash

Pumps are not required and operating costs are reduced.

Filter with 30cm differences of water level after pressurizing unwoven

fine fiber onto the perforated rectangular strainer to form fine pores,

and then backwash after releasing fiber bundles to make the pore wide

for easy and intensive backwash. Its name is GFF (Gravity Flow Fiber)

Filter. When multiple GFF basins are installed, the backwash water are

automatically supplied from adjacent basin's filtrate without back wash pump.

1/100 WTP

1/100 WTP dramatically reduces entire process

time within only 3 mins. as well as 1/100 of treatment volume,

1/5 of construction period and 1/3 of Capex & Opex

while Hyatt (1884, USA) had invented RSF (Rapid Sand Filter

- Coagulation/Sedimentation/Sand filtering) process

to produce tap water 5 hours that is used to almost 100%

of WTP in the world.

1/100 WTP treats about 20 NTU of raw water to

below 0.3 NTU for river water through its own fiber filtration

system in real time. This facility is suitable & designed

for small & medium capacity such as below 20,000 m /day

is container or skid type and bigger capacity is plant type

and especially for the purpose of disaster relief such as earthquake,

etc. is applied to mobile type.

OASIS / WTP-C/db

• Container WTP diffusion brand

Diffusion brand Container type water treatment process

is a process that produces drinking water by using PCF(HS) filter which

is composed of 1 or 8sets of PCF filters, In case of 1set of pcf filter unit,

back wash water is supplied by installed back wash topside tank and

2sets of PCF filter unit, back wash water is supplied by next working

PCF filter. 3 point chemical dosing system will apply to raw water de

pending on turbidity change runs automatic operation,

OPEX is low, easy to control and moving installation.

OASIS / C-WTP

• Container WTP

Container type water treatment process is a process

that produces water by SMiDF(Single Mixing & Double Filteration)

process, which rapidly compounds river or lake water with coagulant

and directly filters the mixture using 2-step PCF.Having 1/100 retention

time by instant coagulation, direct fiber filtration processes taking 3

mins against the conventional coagulation, sedimentation and sand filter

processes taking 300mins, turbidity of treated water is below 0.3

NTU and SDI 3.0, when turbidity of source water in within 20NTU.

Construction period is short and OPEX & CAPEX is low. Container type

using ISO 10, 20, 40, 45ft is designed as the format of 1 or 2 layer.

OASIS / WTP-C/uw

• Container WTP - C/uw

Container type water treatment process for Fe• Mn removal is a

process that when solubility of Fe•Mn exceed

3 times of standard limit for underground water, it will rapidly

oxidation and mix with coagulant using PCF(HS) filter filtrate

plant. It compounds with one oxidizing chamber & one filter

tank and which has for both filtration water tank and back wash

tank located on the upper part and both automatic operation

and manual operation is possible depending on water level

so OPEX is low, easy to control and moving installation.

7. OASIS / M-WTP

• Mobile WTP

mobile type WTP consists of 2 to 6 units of filter which

applies an independent back wash system and back wash water

is supplied from the other filter and activated carbon filtration

device. This full automatic operation is applied with 3 point chemical

dosing system, automated fault diagnosis system and

back wash recycle system.

8. OASIS / P-WTP

• Plant WTP

plant type WTP that is direct filtration process by PCF

fiber filtration with instant mixing of coagulant for raw water

as river or lake water is for medium & big size WTP. It is full

automatic operation system and applied 3 point ch dosing

system, automated fault diagnosis system and back wash water

recycle systemas well as minimized factory space,

construction peirod, Capex and Opex.

9. OASIS / S-WTP

• Skid WTP

skid type WTP consists of 4 to 8 units of filter which

is an independent back washsystem and back wash water is

supplied from the other filter. This is full automatic operation

system and applied 3 point dosing system, automated fault

diagnosis system and back wash water recycle system. Skid

type is available to apply at small place than container type's

by heighten of PCF height and easy to move.

MORE PRODUCT

Fiber Filter

[b]1.PCF Filter (Pore Control Fiber)[b]

Non-woven fine fibers wrapped around the perforated pipe are squeezed,

After filtration, relax it and increase the pore size,

(PCF) filter with a pressure-type fiber filter.

And the reverse filter function is applied to the cartridge filter.

Flexible fiber bundles surrounding the perforated cylindrical

strainer are pulled up to form fine pores at filtration step and

they are released to form rough pore for easy and intensive

backwash. Its name is PCF(Pore Control Fiber) Filter that

is the cartridge filter having backwashing function.